Sortation Systems from Lone Star Automated

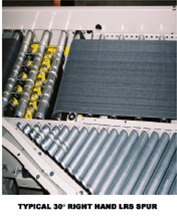

Sortation systems can use several methods to divert product depending on process requirements. In many applications pop up wheel sorters can be used effectively.

Sortation systems can use several methods to divert product depending on process requirements. In many applications pop up wheel sorters can be used effectively.

High Speed Popup Wheel Sorter

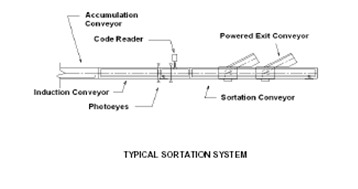

High Speed Pop-Up Wheel Sorters often require automatic code readers. These code readers (laser scanners) read bar codes and tie these codes into automatic tracking through a programmable controller. The code reader can also be interfaced with a customer's computer. Carton data can be transmitted in ASCII format through a RS-232 port. The programmable controller, using impulses from the incremental encoder, tracks each product to its destination and actuates the high-speed wheel diverter at the right time to accomplish the divert.

The sorter induct consists of a brake spacer belt or a brake meter belt, depending on the carton size(s) and sortation rate requirements. The brake spacer induction provides a defined "head to head" case separation based on carton length and is adequate for handling consistent case sizes or a mix of products with small variations in case length. The brake meter belt induction (with the necessary controls) provides a consistent gap between cartons and is commonly used for inducting cartons with wider length ranges.

The sorter induct consists of a brake spacer belt or a brake meter belt, depending on the carton size(s) and sortation rate requirements. The brake spacer induction provides a defined "head to head" case separation based on carton length and is adequate for handling consistent case sizes or a mix of products with small variations in case length. The brake meter belt induction (with the necessary controls) provides a consistent gap between cartons and is commonly used for inducting cartons with wider length ranges.

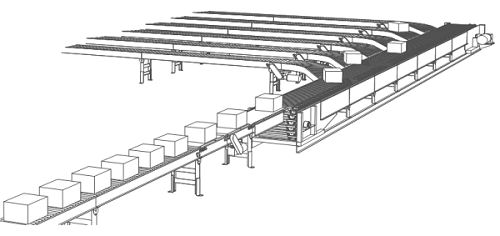

Sliding Shoe Sorter

A sliding shoe sorter is a high rate sortation machine. It is designed to run at speeds up to 600 fpm and sort cartons at peak rates in excess of 200 Cases Per Minute (CPM). Two configurations are available for single or dual sided sorting. The sorter consists of a drive section, intermediate sections with divert modules, infeed tail section and a salve driven infeed belt called a load belt.

Environmental conditions:

A sliding shoe sorter is designed to operate within the following environmental parameters.

Temperature:

- Minimum: 40°F (4°C) ambient (limited by mechanical components)

- Maximum: 104°F (40°C) ambient (limited by

electrical components)