Belt Driven Live Roller Conveyors

Belt driven live roller is a powered conveyor where the load or product is carried directly on carrying rollers. An endless belt (flat or V belt) drives the carrying rollers. Adjustable height pressure rollers located below the carrying rollers engage the belt with the carrying rollers, providing the power to transport the product. BDLR conveyors are designed for level applications that do not exceed 5° of pitch. The product to be conveyed should have a flat and firm conveyable surface and a maximum unit load weight of 150 lb or a live load of 50 lb per ft.

Belt driven live roller is a powered conveyor where the load or product is carried directly on carrying rollers. An endless belt (flat or V belt) drives the carrying rollers. Adjustable height pressure rollers located below the carrying rollers engage the belt with the carrying rollers, providing the power to transport the product. BDLR conveyors are designed for level applications that do not exceed 5° of pitch. The product to be conveyed should have a flat and firm conveyable surface and a maximum unit load weight of 150 lb or a live load of 50 lb per ft.

Belt driven live roller is a commonly used conveyor due to the variety of its applications. Following are a few typical applications:

- Transportation - moving product from one point to another.

- Accumulation - product must be stored or staged.

- Diverting - onto 30° spurs, by manual or automatic means.

- Merging - from extended width sections.

- Pop-up Stops - automatic or manual.

- Changing directions - live roller curves.

Low Pressure Accumulation

This type of belt driven live roller conveyor employs a low friction belt and is used to accumulate loads of a solid, well packed non-fragile nature.

The carrying rollers are equipped with bushings that ride in a 5° angular slot. The high side of the slot is opposite the direction of load travel. As the load moves along the conveyor, the carrying roller bushings rest at the bottom of the slot.

As soon as the load meets an obstruction, such as a blocked load, the belt motion causes the carrying roller bushings to roll up the angular slot, thus relieving some of the pressure between the belt and carrying rollers under the load.

As soon as the load meets an obstruction, such as a blocked load, the belt motion causes the carrying roller bushings to roll up the angular slot, thus relieving some of the pressure between the belt and carrying rollers under the load.

The line pressure developed from the accumulation of loads varies depending on such factors such as size, shape, and weight of loads, but, in general, the line pressure exerted on the lead carton averages 4% to 6% of the total accumulated weight on the conveyor.

Two models of low pressure accumulation are available: an end drive that has a 325 lb effective belt pull capacity and a model that is equipped with a center drive and has a 650 lb effective belt pull capacity.

Zero Pressure Conveyor

Zero Pressure Conveyor is a belt driven, zone accumulating, live roller conveyor. It is driven with a flat continuous belt. Pressure rollers, mounted in short sections, are raised vertically by air pods to bring the belt into contact with the underside of the carrying rollers to provide the driving force. Pressure rollers are lowered during accumulation. See Figure 1a & 1b Cross Sections for reference. Mechanical sensor rollers or photoelectric sensors control the flow of product and are located in each accumulation zone. Two different zone lengths and carrying roller centers are available to convey a wide range of carton sizes. Multiple modes of operation, for mechanically and photoelectrically controlled conveyors, are available for meeting a wide range of throughput rates and application requirements.

Zero Pressure Conveyor is designed for horizontal, non-reversing applications operating at speeds up to 300 feet per minute with the following benefits:

- Zero line pressure when product is accumulated.

- Singulation, Slug, or Smart Release Modes of operation for mechanical sensor rollers.

- Smart release allows sensor rollers to remain below carrying surface until needed, reducing marring of product, and increasing life of the equipment.

- Dual sensor rollers accumulate product with tapered ends such as totes.

- Conveyor lengths up to 196 ft long can be powered by a single drive.

- Programmable 120VAC photoelectric mode of operation (PZC - Programmable Zone Control) available.

- DC Accumulation with 24VDC photoeyes is available in two modes of operation, singulation and slug release.

Line Shaft Live Roller

Line Shaft is a live roller conveyor driven by a shaft which runs the length of the conveyor. Each roller is individually driven by an elastomeric belt connected to a slip fit drive spool on the line shaft. Since several components can be powered by one motor, Line Shaft is an economical solution in many applications. Line Shaft conveyors are ideal for applications such as clean rooms, electronic assembly areas and pharmaceuticals to create a clean, quiet, and flexible system. Loads up to 60 pounds per foot can be moved at standard speeds up to 120 fpm.

Bolted construction and quick-coupled shafting easily accommodate changes or additions. Individual rollers or sections of the conveyor can be customized to create non-powered work stations, accumulation areas, or reverses in direction of travel on a common driveshaft.

Line Shaft conveyor requires fewer drives and controls resulting in lower energy consumption and lower installation and maintenance costs than conventional conveyor.

Line Shaft conveyor should be considered when the following conditions exist:

- Low case rate.

- Clean and dry application.

- Quiet application.

- Short conveyor runs with a high number of components.

Line Shaft conveyor should not be considered when the following conditions exist:

- Wet or oily environment.

- Abrasive or corrosive environment.

- Elevation changes.

- On conveyors over 200 ft long with one drive.

Powered Roller

Powered roller is a live roller conveyor where the load or product is carried directly on the carrying rollers. The carrying rollers are driven from 24Vdc motorized rollers that are strategically located along the length of the conveyor in transportation or accumulation zones. Drive belts, 3/16" diameter urethane, connect the motorized roller to carrying rollers in each zone.

Powered roller is a live roller conveyor where the load or product is carried directly on the carrying rollers. The carrying rollers are driven from 24Vdc motorized rollers that are strategically located along the length of the conveyor in transportation or accumulation zones. Drive belts, 3/16" diameter urethane, connect the motorized roller to carrying rollers in each zone.

Powered roller conveyor is designed for level transportation and zero pressure zone accumulation applications. Equipped with 3" wide flat belts, Powered roller conveyor can be used in inclining and declining applications up to 5 degrees and loads weighing up to 75 lbs. Greater angles of incline can be achieved with lighter loads.

Powered roller conveyors can be comprised of several sections, each of which may consist of several zones. The conveyor can be as short as a single zone.

V-Belt Driven Live Roller

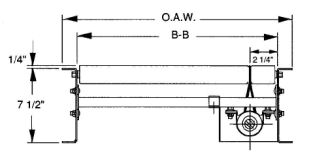

V-belt driven live roller curves, spurs, and skewed live roller are designed to transport product and should not be used for accumulation. All rollers are driven by a continuous "B" size V-belt. Pressure sheaves hold the V-belt against the underside of the carrying rollers. To prolong belt life, the pressure sheaves should be set to provide just enough contact between the belt and carrying rollers to move the product without stalling.

The preferred end for driving all belt driven live roller units is at the infeed end. However, lightly loaded curves, can be driven successfully from the discharge end.

When diverting to a spur or spur-curve at a 30° or 45° angle, the speed of the spur should be set to run 15% faster than the conveyor feeding it. Conversely, if the product flow is reversed with travel from the spur to a takeaway conveyor the spur speed should be set 15% slower than the take-away conveyor.

Skewed Live Roller Conveyor

Skewed live roller conveyor is sometimes used at the infeed end of an accumulation conveyor to align the packages to one side of the conveyor. Typical applications for edge alignment include: accumulation of multi-width cases, sortation, and bar code scanning.

**The minimum width case that will edge align according to the skew and overall length of the conveyor. The minimum width dimension assumes the case enters the skewed live roller conveyor along one guardrail and travels the full width across the conveyor to the other guardrail at the discharge end. Capacity of 400 lbs total live load, maximum unit load of 150 lbs. Normal-to-heavy corrugated cardboard with flat bottom is preferred. Minimum box height = 1". For applications with open flaps or totes, consult factory.

Product should be presented to the skewed live roller conveyor with gaps between the cases for optimum operation. There is always a potential for cases that are square or wider than they are long, to spin around as they make contact with the skate wheel guardrail.

Flexible Powered Roller Conveyor

Flexible powered roller conveyors are ideally suited for truck loading and unloading, distribution centers, packaging, portable assembly lines, shipping and receiving. It is available with numerous options including accumulation capabilities.