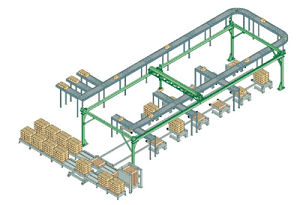

Complete Turnkey Palletizing Systems

Boxes or bags, round or rectangular, Lone Star can supply the means to convey and palletize your products. There are three main types of palletizing methods using automation: Conventional, Articulating-Arm Robotic, and Gantry Robotic - each being the right solution for a specific application. Conventional or robotic, semi-automatic or automatic, pull-sheets or pallets- all palletizers/unitizers are focused on the same goal: stacking cases, bags and other units in a uniform pattern. Palletizing patterns can be easily modified via an HMI.

The difference in their designs provides that the strong suit of conventional palletizers is speed while robotic is flexibility. Conventional palletizers have a broader range of speeds, anywhere from 10 to 200 cases per minute. Articulating-Arm Pick-and-Place robotic palletizers are often a good choice for lower-volume/multi-SKU operations as they can build up to four pallets from four different product lines simultaneously. Gantry Automation can handle multiple products with aggressive throughput rates. The footprint and functionality of robotic area gantries can be expansive- or compact - depending on your needs.

Lone Star can help determine which solution is the right fit for your application.

Conventional Palletizers

Conventional palletizers come in numerous configurations - side entry or inline; floor level or high level infeed, right or left hand. Typically the higher the case rates the larger the footprint of the machine. Palletizers have moved away from hydraulic type units to electrics and pneumatics.

A new evolution in palletizing is a "hybrid" that uses a combination of the basic flexibility of a traditional robotic palletizer with the simplicity and maintainability of a conventional/traditional palletizer (industry standard components such as PLCs are used throughout). This accomplishes a lower cost machine that provides for a fully automated palletizer including infeed conveying, pallet dispensing and handling, and slip sheet handling. The total cost of a hybrid system in most instances will be less than the cost of a basic robot arm.

Robotic Articulating Arm

An Articulating-Arm robotic palletizer's design allows it to function in low ceilings and with limited workspace, maximizing the working envelope. Palletizer space is essential for companies looking to maximize their space and minimize time and labor costs.

The Features:

- Uses electric servo-drives

- Is easily introduced into any existing material handling system configuration

- Allows for a variety of end effectors

- Has the ability to palletize multiple or individual package types

- Provides an easy user interface

Gantry

Gantries are similar to a very precise crane. They have two beams that support a moving bridge. The bridge has a moveable carriage that supports a vertically moveable rigid beam with an end-effector attached. Gantries can operate over large work spaces, perform many tasks in that envelope, and position units to a high degree of accuracy. Payload capacity can be thousands of pounds.

Gantries are similar to a very precise crane. They have two beams that support a moving bridge. The bridge has a moveable carriage that supports a vertically moveable rigid beam with an end-effector attached. Gantries can operate over large work spaces, perform many tasks in that envelope, and position units to a high degree of accuracy. Payload capacity can be thousands of pounds.

The Features:

- Greater volume coverage

- Limitless layout options

- Flexible work envelope

- Diverse pick-up and delivery points

- Accommodates heavy payloads

- Variety of end effectors available

Bulk Palletizers

Bulk palletizers are designed primarily for the needs of the PET bottling industry, offering high level and low level options as well as automatic or semi-automatic models.

Bulk palletizers are designed primarily for the needs of the PET bottling industry, offering high level and low level options as well as automatic or semi-automatic models.

Low Level Features:

- Low-level design eliminates operator stairs and platform

- No downed bottles, no voids in the layer pattern

- Easy bottle change-over

- Available in "C" flow or standard flow layouts

- Single aisle dunnage access and full pallet removal

- Capacity to palletize bottles from two blow molders

High Level Features:

- Up to 40,000 bottles per hour

- Easy bottle change-over

- Row-forming design

- One-to-six servo-operated gate

- Multi-lane bottle drop onto vacuum table

- Layer capture with stabilizing bars